Product:

Specification:

injection screw barrel and bimetallic injection screw and barrel by materials 38CrMoAlA or 42CrMo and so on,for many type of injection mould machines,such as HAITIAN,CHEN HSONG,JSW,HAITAI,BRCHO,and so on.

1. Diameter of screw: D12-D300mm

2. L/D ratio of screw: 10 – 26

| Technical Parameter | |

|

Base Material

|

1)38CrMoAlA(JIS SACM645);2)Cr12MOV(JIS SKD-11) ; 3)4Cr5MoSiV1(JIS SKD-61) ;4)42CrMo(AISI 4140) |

| Bimetallic Alloy Materials | 1)Fe-based alloy 2)Ni-based alloy/Deloro alloy 3)Co-based alloy 4)NiCo-based alloy 5)Tungsten carbide/Wolfram carbide |

| Double-alloy level | Level A – containing Tungsten of 40% Level B – containing tungsten of 25% Level C – containing tungsten of 15% |

| Surface Treatment | Heat Treatment High Frequency Treatment Nitriding treatment(120 Hours): Depth of Nitrided Layer: 0.5-0.8 mm Hardness of Nitrided Layer: 900-1020Hv (HRC56°-65°) Hard Chrome Plating treatment: Thickness of Hard Chrome Plating Layer: 0.05-0.10mm Hardness of Hard Chrome Plating Layer: ≥950HV Nickel alloy plating.treatment: Bimetallic Barrel/Cylinder: Centrifugal Casting (Inlay Alloy) Bimetallic Screw: Plasma Alloy Coating Spraying Depth of Bimetallic Layer: >2mm Hardness of Bimetallic Layer: HRC55°-72° Spraying corrosion wear-resisting dual metal layers |

| Basic information | Roughness of the surface:Ra0.4um Linearity of the screw: ≤0.015mm Linear axis limit: ≤0.02mm Hardness after Hardening & Tempering: HB240-280 Fragility of Nitration:≤Two class |

| Material Application | 1)General Plastics 2)ABS,PA,PC,PE,PET,PP,PS,EVA,PU,PVC,U-PVC,etc 3)PA + GF(Glass Fiber) 4)Flame-resistant Reinforced Plastics 5)Modified Engineering Plastics 6)All kinds of Mixed Recycled Material(in Scrap or Granule), PVC + 30% CaCo3, etc |

***Grade available:

1. Standard grade: 38CrMoAlA + nitriding 96 hours

2. Bimetallic grade: 38CrMoAlA + bimetallic alloy

Material

1)38CrMoALA(JIS SACM645)

2)42CrMo(JIS SCM440)

3)9Cr18MoV

4)CW6Mo5Cr4V2

5)Various high quality alloy steels,According to different usage, the choose for alloy is different, some require for abrasion-resistant while some require for corrsion-resistant. For standard, we have Fe-based, Ni-based,W2Calloy,Tunsten alloy etc for choice.

6)The foreign material we used as following:

*Germanysteel, GH113 ,2250 ,2842 ,1.8509 ,1.442 ,1.6582 ,1.6523 ,1.2080,1.4542,

*USA steel, P20,420,L6,H13,W110,D3,A2,D6,O1,S1,M35,8620,3115,K52440

*Sweden steel, 718S,718H,S136,S136H,STAVAX,ASP-23,ASP-30

*Australia Steel, M202,M300,W302,K460,W300,K900,K100,W321

*Hardness steel, YG6X,YG 6A,YG 6,YG8N,YG8,YG8C,YG11C,YG 15,YT5,YT14,YT30

*Japan Steel, SKT 4,YXM 4,YXM 42,SNC 815,SK -3,SKS 3,and etc.

Instructions for our Screw&Barrel:

1.We are a professional company specialized in manufacturing many types of screw, the barrel can be applied on all types injection screw barrel of injection moulding machine,rubber hot-feeding extruder, rubber cold-feeding extruder, pin barrel cold feed extruder, plastic extruder with different specifications.

2.The models of screw include:

Variable pitch and variable depth, variable pitch and equal depth, variable depth and equal pitch, and equal depth and pitch.

Groove multi-die type, composite type, mixing type and separating type.

3. The material of screw: manufactured with high-quality nitro alloy steel, applying the method of hardening and tempering and nitriding, thus it enjoys the characteristics of long working life, wear resistance, and anti corrosion. Besides, the technique of hard alloy spraying or chrome plating can be used on the working surface of screw, which will make it have better using effectiveness

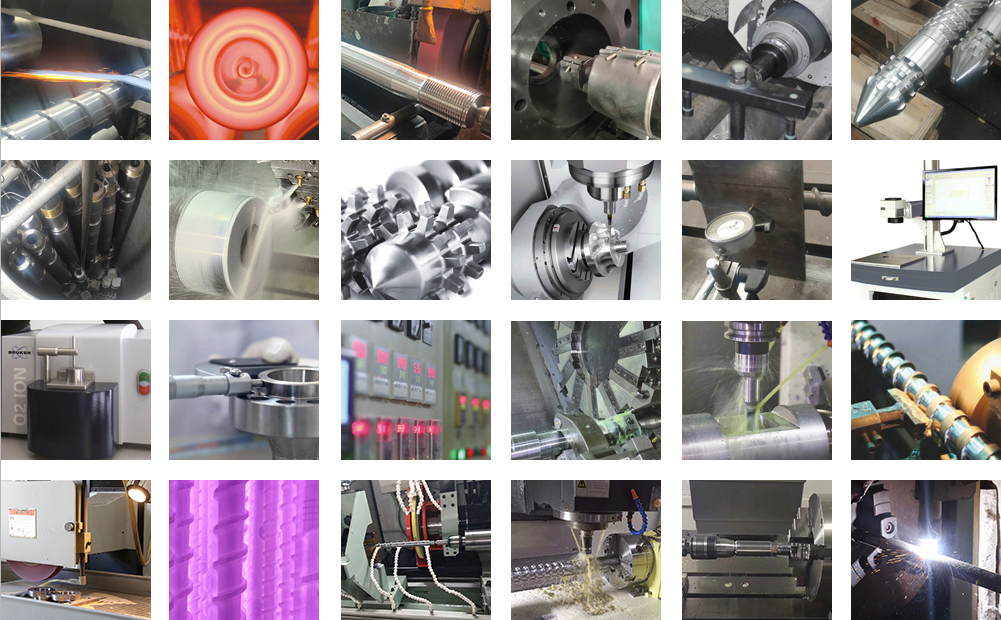

Workshop&Process

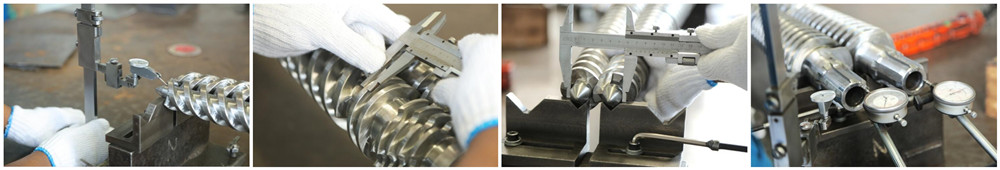

Quality Inspection

Packing&Shipment