Rubber screw barrel

Product: Rubber screw barrel

Material:38CrMoAIA/SACM645/AISI4140/SKD61/etc

Nitriding depth:03.5-0.8mm

Alloy depth:2.0-3.0mm

Quenching hardness: HRC55-62

Surface roughness:Ra0.4

Screw straightness:0.015mm

Origin: China

Product:

Specification:

Pin-cold feed rubber extruder screw screw and barrel for extruder rubber processing machine

Screw diameter:Φ15mm-Φ360mm L/D=15-56

Length of screw and barrel/cylinder:8000mm

According to different material and plastic products to design different screw structure ,compress rate and L/D!

According to different material and plastic products to design different Barrel with exhaust system and IKV force load system!

As per customers’ demand,we can supply below:

PVC/PE Film Blowing Screw; Blow Molding Screw; PS/PE/PP/ABS Sheet Extrusion Screw; PE Aluminum Plate;PPR Pipe Screw;EVA Extrusion Screw;HDPE High efficiency Screw;PET Straps Screw;XPS/EPE Foamed Screw;Granulation Screw,Vented single screw etc!

Extruder screw diameter: 15 – 300 MM

LD for extruder screw: 1:5 – 1:65

Extruder barrel OD: 20-500 MM

| Technical Parameter | |

|

Base Material

|

1)38CrMoAlA(JIS SACM645);2)Cr12MOV(JIS SKD-11) ; 3)4Cr5MoSiV1(JIS SKD-61) ;4)42CrMo(AISI 4140) |

| Bimetallic Alloy Materials | 1)Fe-based alloy 2)Ni-based alloy/Deloro alloy 3)Co-based alloy 4)NiCo-based alloy 5)Tungsten carbide/Wolfram carbide |

| Double-alloy level | Level A – containing Tungsten of 40% Level B – containing tungsten of 25% Level C – containing tungsten of 15% |

| Surface Treatment | Heat Treatment High Frequency Treatment Nitriding treatment(120 Hours): Depth of Nitrided Layer: 0.5-0.8 mm Hardness of Nitrided Layer: 900-1020Hv (HRC56°-65°) Hard Chrome Plating treatment: Thickness of Hard Chrome Plating Layer: 0.05-0.10mm Hardness of Hard Chrome Plating Layer: ≥950HV Nickel alloy plating.treatment: Bimetallic Barrel/Cylinder: Centrifugal Casting (Inlay Alloy) Bimetallic Screw: Plasma Alloy Coating Spraying Depth of Bimetallic Layer: >2mm Hardness of Bimetallic Layer: HRC55°-72° Spraying corrosion wear-resisting dual metal layers |

| Basic information | Roughness of the surface:Ra0.4um Linearity of the screw: ≤0.015mm Linear axis limit: ≤0.02mm Hardness after Hardening & Tempering: HB240-280 Fragility of Nitration:≤Two class |

| Material Application | 1)General Plastics 2)ABS,PA,PC,PE,PET,PP,PS,EVA,PU,PVC,U-PVC,etc 3)PA + GF(Glass Fiber) 4)Flame-resistant Reinforced Plastics 5)Modified Engineering Plastics 6)All kinds of Mixed Recycled Material(in Scrap or Granule), PVC + 30% CaCo3, etc |

***Grade available:

1. Standard grade: 38CrMoAlA + nitriding 96 hours

2. Bimetallic grade: 38CrMoAlA + bimetallic alloy

Material

1)38CrMoALA(JIS SACM645)

2)42CrMo(JIS SCM440)

3)9Cr18MoV

4)CW6Mo5Cr4V2

5)Various high quality alloy steels,According to different usage, the choose for alloy is different, some require for abrasion-resistant while some require for corrsion-resistant. For standard, we have Fe-based, Ni-based,W2Calloy,Tunsten alloy etc for choice.

6)The foreign material we used as following:

*Germanysteel, GH113 ,2250 ,2842 ,1.8509 ,1.442 ,1.6582 ,1.6523 ,1.2080,1.4542,

*USA steel, P20,420,L6,H13,W110,D3,A2,D6,O1,S1,M35,8620,3115,K52440

*Sweden steel, 718S,718H,S136,S136H,STAVAX,ASP-23,ASP-30

*Australia Steel, M202,M300,W302,K460,W300,K900,K100,W321

*Hardness steel, YG6X,YG 6A,YG 6,YG8N,YG8,YG8C,YG11C,YG 15,YT5,YT14,YT30

*Japan Steel, SKT 4,YXM 4,YXM 42,SNC 815,SK -3,SKS 3,and etc.

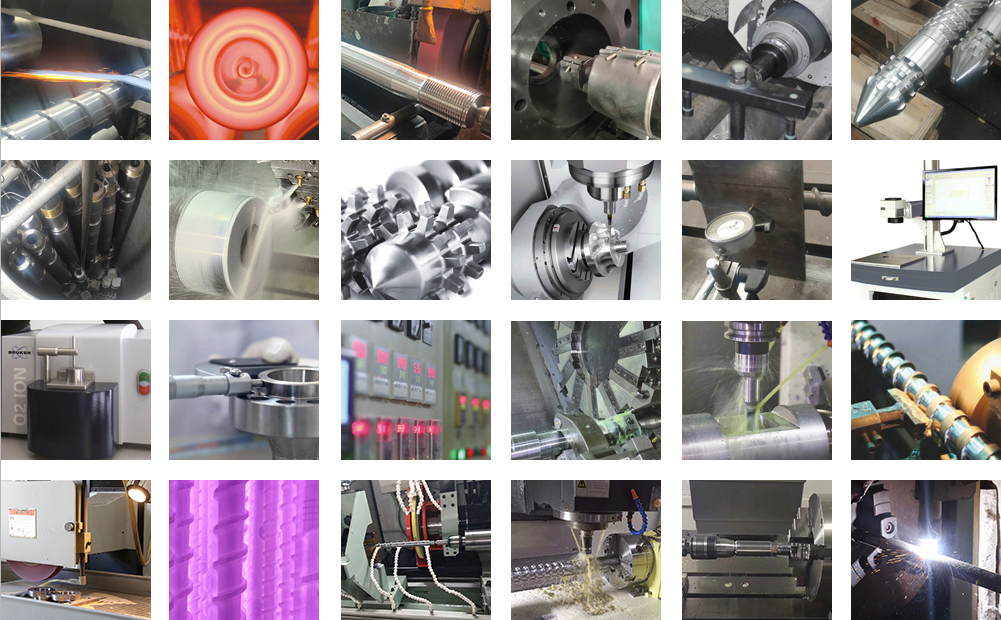

Workshop&Process

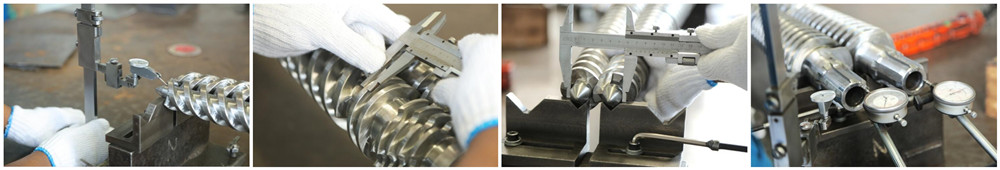

Quality Inspection

Packing&Shipment