Planetary Screw Barrel

Product: Extruder screw barrel

Material:38CrMoAIA/SACM645/AISI4140/SKD61/etc

Nitriding depth:03.5-0.8mm

Alloy depth:2.0-3.0mm

Quenching hardness: HRC55-62

Surface roughness:Ra0.4

Screw straightness:0.015mm

Origin: China

Product:

Specification:

Planetary screw extruder is composed of central shaft, planetary shaft, rolling stuff barrel, case, heating and cooling parts, rozzel, and so on.

The structure uses model system, and has good flexibility.

Planetary screw extruder mainly are used for manufacturing thermal sesitivity materials hard and soft PVC and also for ABS, TPO, TPU, and the mixture of filler polyalkene and bond.

Screw type: Planet screw/Planetary screw

Main screw size: 75mm~190mm

Accessories screw quantity: 6~12

Screw L/D: 10-46

|

Planet Screw Barrel/cylinder planetary screw for plastic extruder Machine |

|||

|

Diameter |

Φ70mm-Φ190mm |

Design |

Screw structure and compression ratio can be designed According to different products & different clamping force requirement. We can select&design the matching screw barrel to meet your requires. |

|

Materials |

38CrMoAlA |

Application |

All kinds plastic & rubber and All kinds of glass fiber, |

|

Nitride Case Depth |

0.5mm-0.8mm |

Technology |

1.Longer time Gas Nitriding |

|

Nitride Hardness |

960-1060HV |

Packing |

Wrapped up by film in wooden |

|

Surface Roughness |

Ra0.4um |

Delivery Term |

25 working days |

|

Screw Straightness |

0.015mm |

Port Departure |

Shanghai/Ningbo |

|

Alloy Hardness |

HRC58-70 |

Min. Order |

1 set |

|

Alloy Depth |

1.5mm-3.5mm |

Guarantee |

Common Nitrided:2.5-4years |

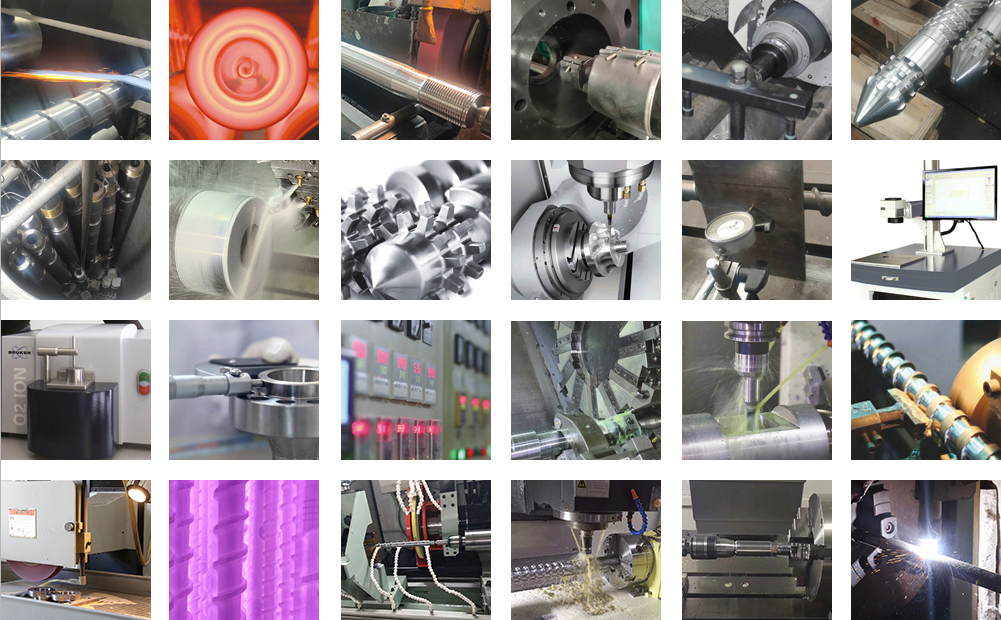

Workshop&Process

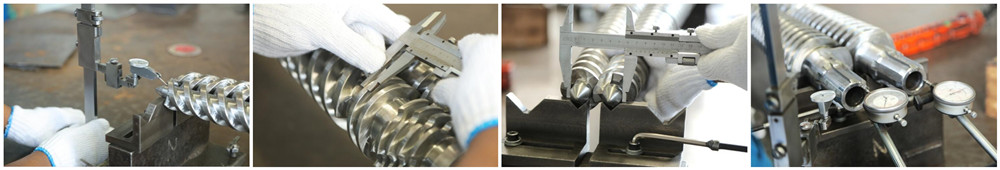

Quality Inspection

Packing&Shipment